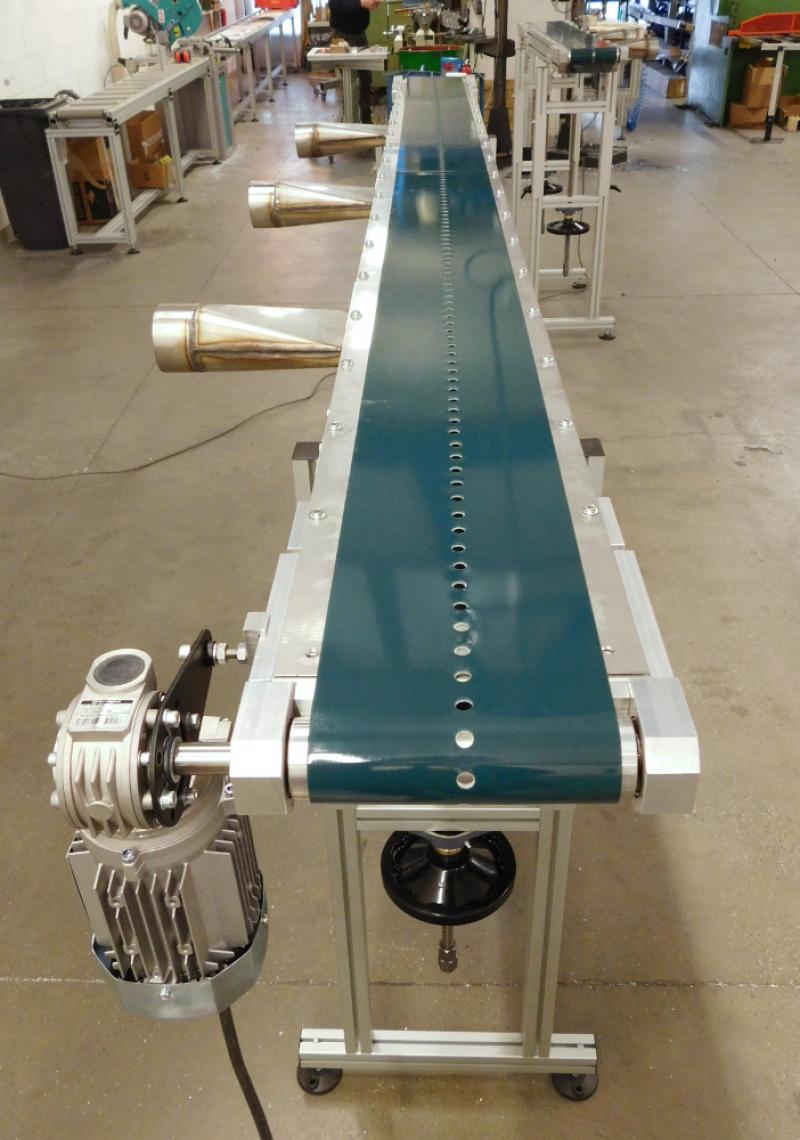

Belt conveyors

Chip conveyors, shredders, trolleys

Multi-Purpose Conveyor Belt Systems Instantly

The prosperity of management in almost any industrial enterprise depends upon certain specific factors. Streamlining the entire process of logistics for max production whatsoever possible time is one. This is done through the movement of recyclables and handle products in the very best manner. For this finish, conveying systems are actually the perfect modes specifically in projects associated with infrastructure and mega industries. Indeed, scalping strategies might be referred to as the vital veins of commercial activities, nay the sphere of socio-economic development.

Thus, the makers of those systems contain the answer to the march from the progress. They design and fabricate the trasportatori di sfrido as reported by the users needs and in tune using the standards prescribed by designated agencies of quality and safety. These belts are extensively utilized in mining, power, cement, fertilizer and steel plants, various production lines in factories, airports, railway stations, goods yards, ports, warehouses, granaries etc. Thinking about these details, it may be appropriately stated the technology along with the industry involved in making scalping strategies have great significance.

Mastering the skill of conceptualizing, manufacturing and commissioning material handling systems for lighter and bulk quantities, the main makers and suppliers of those systems provide the following services and products:

Crushing and screening

Sampling Station

Stacking and reclaiming

Bagging system

Overland belt conveyors

Pipe conveyors between mines and processing plant

Tipplers for unloading from wagons

Track hopper and unloading hopper

Manufactures of those systems involve numerous components and allied engineering for example steel tubes for idlers, pulleys and rollers. Idlers, though united nations-powered, are considered is the heart of the conveyor. It's of these machines the belt moves in the controlled speed.

The gear have direct effect on the sturdiness of the belt system. They minimize belt fleet and damage around the return belt which may otherwise derive from material build-up. They safeguard the belt against abrasives during the whole process of a method. Some primary kinds of these idlers receive.

Quality idlers are anticipated to become weather-proof including corrosion resistant for that smooth operation of the conveyor belt system. The idlers synchronize both vertical and horizontal movement of the conveyor belt. The services and products of idler and roller manufacturers are retained by turnkey consultants within the execution of fabric handling systems of major projects.